| TZ 2 5,5/12-17 |

TZ 3 5,5/12-23 |

TZ 3 7,5/16-23 |

TZ 3 7,5/20-23 |

TZ 5 7,5/25-35 |

Max. | |

| Max. detail diameter (mm) |

1200 | 1600 | 2000 | 2500 | 2500 | |

| Max. detail height (mm) |

1700 | 2300 | 3500 | 3500 | ||

| Hook capacity (kg) | 500/1000 | 1000/2000 | 2000 | |||

| Number of turbines | 2 | 3 | 3/4 | 5 | 5 | |

| Turbine power (kW) | 5,5/7,5 | 7,5/11 | 11 | |||

| Blasting wheel speed (rpm) |

2900 | 2900 | ||||

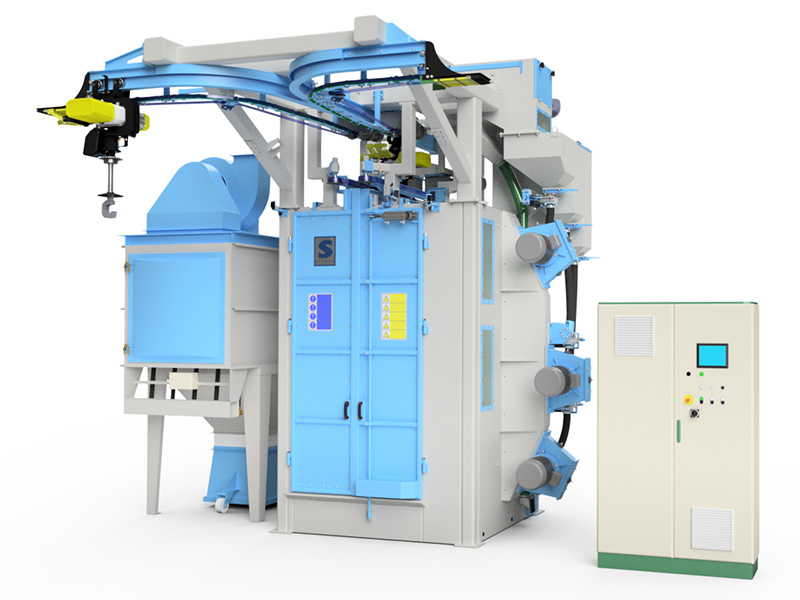

Alumetal-Technik deals with many methods of surface cleaning, but the shot blasting is particularly important. The common passion for the blasting process is the basis of our cooperation with the Kovo Staněk company, the Czech producer of wheel blasting machines.

Produced in Brumovice TZ hook-type blasting machine is the basic model in our offer, in which applied many innovative solutions, not available in competition machines.

The blasting chamber of TZ wheel blasting machines is made of massive, abrasion-resistant steel. Details are entered inside on one of two hooks placed on Y-shaped rail. This construction allows preparing the next batch of elements during the blasting process.

The big advantage of Kovo Staněk’s machines is MT 350 turbines with extended life-time. It was accomplished by usage of double-bearing of the electric motor shaft. The tension on this part is reduced, which means lower exploitation and service costs.

An operator can control the machine through the touch screen. It allows to modify every parameter – turbines’ power, blasting time, hooks’ movement etc. Every programme can be saved in the device memory.

Unique construction solutions make the TZ the safe, economic and flawless blasting machines. Every parameter – sizes, hooks capacity, turbines power etc. – can be adjusted to customer’s requirements. If you are interested in test and bought the TZ wheel blasting machine just contact us via phone, e-mail or contact form.