One of the biggest problems in the surface treatment industry is the instability of the shot blasting process. Lack of repeatability and dustiness result in more frequent complaints, which generate unnecessary costs. That is why we decided to help entrepreneurs in maintaining the cyclical nature of the process and generating related savings.

How does VERA® steel shot work?

Over the years of experience in the abrasives market, we have defined several problems with the use of spherical grits (particularly in blasting machines). They concern, among others:

- No cyclicality of the blasting process;

- Incorrect separation;

- Too fast wear of machine parts (e.g. blades, filtration system);

All this adds up to high shot blasting costs, which can be easily reduced.

Why is it worth using VERA® steel shot?

Manufacturers focus on solving the above problems already at the stage of manufacturing VERA® steel shot. During the production processes, it is thoroughly cleaned of scale and dust, which can

constitute up to 10% of the volume of other abrasives. This means that when ordering 1 ton, the customer will actually receive 1 ton of VERA® steel shot, not 920 - 950 kg as in other cases. Thanks to such preparation of the abrasive for sale, the shot blasting process is carried out without unnecessary dust, which translates into less filter wear.

Compared to standard abrasives,

VERA® steel shot doesn’t crack and wears slowly. Thanks to this, it doesn’t damage the machine and the details surface. In addition, it wears very slowly, which translates into repeatability of the process and

an increase in efficiency by up to 40%.

What does cooperation with us look like?

Hybrid steel shot VERA® - for whom?

VERA® steel shot is most often used in industries such as: steel constructions, agricultural machinery, medical furniture, foundry, forges, automotive, screws and bolts and many others. It helps to solve the problems of technologists and production managers, financial directors and owners of metalworking companies.

| Finance Director |

Technologist / Production Manager |

Owner / CEO of the company |

| · reduction of the annual costs of the shot blasting process;

· less frequent expenditure on abrasive material;

· less frequent service inspections and purchases of spare parts (including filter cartridges);

· extending the life of the machine will save up to 30-40% on the shot blasting process. |

· reproducible surface quality;

· the lowest surface salinity on the market;

· no scale or dust;

· no complaints due to faster and more accurate blasting;

· maintaining production continuity through slower consumption of shot. |

· minimizing costs in the company while increasing efficiency;

· care over the shot blasting process through systematic advice, analysis and testing;

· reduction of the annual costs of the shot blasting process;

· increasing the throughput of the shot blasting process;

· less frequent expenses in other areas (services, machine repair). |

How much does VERA® cost?

We are the sole distributor of the Eisenwerk Würth foundry, therefore we buy and sell abrasive based on the variable scrap surcharge and the energy surcharge. These allowances are regulated on a monthly basis. The base price is added to the product price, which also includes the cost of transport to the customer. The total cost gives the final price of steel shot VERA®. The price is calculated so that we can provide the highest quality spherical shot on the market and at the same time take care of the client in the testing phase and the implementation of the material in his company.

Characteristics of steel shot VERA®

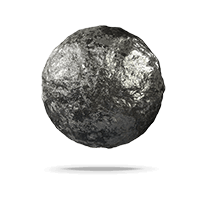

Hybrid steel shot VERA® is a modern and ecological reusable abrasive, ideal for processes requiring high precision and repeatability. It is a hybrid combining the high intensity of high-carbon pellets with the durability of low-carbon pellets. In addition, steel shot VERA® increases its hardness during operation, which maintains the efficiency of the process, despite the fact that the grain diameter decreases during shot blasting.

New Grain: HV 1.0 approx. 420-480 = HRC 42.7-47.7

Operation Mix: HV 1.0 approx. 460-520 = HRC 46.1-50.5

How to test the steel shot VERA®?

Before deciding to buy an abrasive, we offer the opportunity to test it. Tests can take place at the Alumetal-Technik Service Center in Łódź, where we have Kovo Staněk blasting machines

We offer two testing paths for steel shot VERA®:

- Customer's arrival to the Alumetal-Technik Service Center in Łódź – the Customer brings his details and participates in the tests. Thanks to this, he has the opportunity to physically touch and check the abrasive and ask questions on an ongoing basis.

- Sending the details by the customer to our Service Center - the Customer sends the details on which he wants to test the steel shot. We clean them, describe them, take measurements (e.g. surface roughness), and then send them back.

If you are interested in checking steel shot VERA® on your details, please contact our Customer Service Office (go to the Contact tab). To get to know the offer for abrasive, just fill out the contact form (click on the Quick quote window).