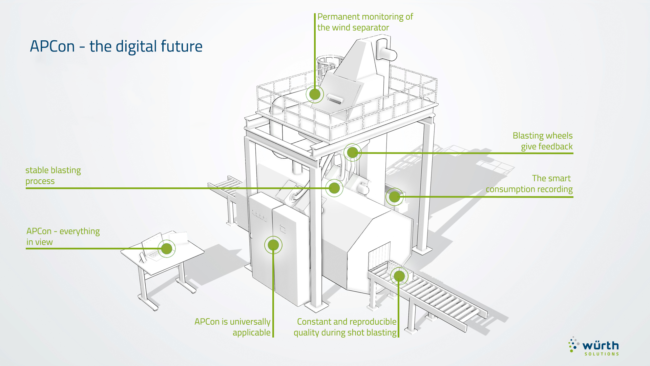

In today’s manufacturing environment, adapting processes to changing market demands is crucial. The APCon system, offered by Würth Solutions, is an innovative digital solution that enables real-time monitoring and optimization of the shot blasting process. Thanks to APCon you can achieve even higher levels of efficiency, quality and savings.

The APCon system is an advanced digital solution dedicated to monitoring and controlling the shot blasting process. Thanks to APCon, it is possible to obtain a precise understanding of the process based on real data. This provides the foundation for higher production efficiency.

The APCon system allows you to observe the shot blasting process in real time from anywhere and at any time. Thanks to intelligent algorithms, it adjusts the machine’s operating parameters. Thanks to automatic data collection and real-time analysis, users can quickly react to any irregularities and optimize the operation of the production line.

The APCon system solves key problems related to the shot blasting process. By precisely monitoring and controlling the operating parameters of the shot blasting machine, APCon significantly reduces the risk of complaints by ensuring constant quality of surface treatment. Moreover, the system enables optimization of electricity and abrasive consumption, which leads to lower production costs. With APCon, companies can avoid unplanned process downtime, ensuring production continuity while saving resources and increasing efficiency.

The biggest advantages of using the APCon system in enterprises are:

The APCon system is dedicated to companies from various industries that use the shot blasting process. It will work particularly well in enterprises that are looking for a solution that allows significant savings while maintaining high production quality.

Directors, presidents, production managers and technologists, the APCon system can help in:

The final cost of the APCon system depends on the size of the machine, the number of turbines and the number of sensors that will be installed in the shot blasting machine. By sending us basic data about your blasting machine, we will be able to prepare a preliminary estimate for the implementation of the system, including installation, commissioning and operator training.

If you are interested in implementing the APCon system in your company or want to obtain more information, please contact us. Our team of experts will answer your questions and prepare an offer tailored to your needs. Click here to go to the form.